Spring 1940, while Nazi panzers rolled through France and the Luftwaffa terrorized European skies, a 45-year-old engineer named Edgar Schmood sat in a cramped North American aviation office in Englewood, California, sketching what would become the most important fighter plane of World War II. But here’s the twist. Nobody asked him to design it. The US Army Airore hadn’t issued a contract. They hadn’t even hinted they wanted a new fighter. Schmood was operating on pure calculated risk, and if he got it wrong, his company would eat the development costs, and he’d probably be looking for a new job.

Edgar Schmood’s story reads like a Hollywood script, except it’s real. Born in Hagen, Germany in 1899, he’d grown up watching the Wright brothers demonstrations in Europe and became obsessed with flight. After World War I, he worked for Fauler in Holland. Yes, that Fauler, the company that built the Red Baron’s triplane. When the Great Depression hit, he immigrated to America in 1930 with nothing but engineering drawings and ambition. By 1936, he’d landed at North American Aviation, a scrappy California company that mostly built training planes.

They weren’t Lockheed. They weren’t Boeing. They were the underdogs. In April 1940, the British Purchasing Commission knocked on North American’s door with an urgent request. Britain was bleeding aircraft faster than factories could replace them, and they needed fighters, lots of them, immediately. They asked North American to build Curtis P40 Warhawks under license, standard procedure, safe money. But company President James Dutch Kindleberger and Schmood saw something else. An opportunity to leapfrog everyone. Schmood told the British representatives something audacious.

We can design you a better fighter from scratch in 120 days. The Brits thought he was insane. His own colleagues thought he was insane. You don’t design a combat aircraft in 4 months. It takes years of testing, wind tunnel work, prototype failures. But Schmood had been secretly working on advanced fighter concepts for months, obsessing over a single problem that plagued every fighter of the era. Range. The Spitfire was brilliant in a dog fight, but ran out of fuel after 400 m.

The P40 had decent range, but couldn’t climb fast enough. German Mi 109’s were lethal interceptors, but tied to their airfields by tiny fuel tanks. Every air force on Earth faced the same brutal trade-off. You could build a nimble fighter or a long range fighter, but not both. Physics wouldn’t allow it. Except Schmoud believed physics could be bent with the right-wing design. The British, desperate and running out of options, signed the contract on May 29th, 1940. 120 days to first prototype.

It was impossible. Schmood assembled a team of 150 engineers and draftsmen, and they worked 24-hour shifts in rotating crews. His secret weapon wasn’t just caffeine and determination. It was data from NACA, the National Advisory Committee for Aeronautics. They’d been testing a radical wing shape called a laminer flow air foil. And Schmoud was about to bet his entire career that it would work not in a wind tunnel, but in combat at 400 mph with someone shooting at you.

October 26th, 1940, just 178 days after the British contract signature, test pilot Vance Bree lifted the first NA73X prototype off the runway at Minesfield in Los Angeles. The plane felt light, responsive, almost eager. Bree pushed it through rolls and climbs, and when he landed, he told Schmoud something engineers dream of hearing. This thing handles like a sports car. Within weeks, the British christened it Mustang, and initial reports seemed to validate Schmoud’s impossible gamble. The plane was fast, 390 million in level flight, faster than almost anything in the sky.

It was smooth. It was stable and then pilots took it into combat altitude and everything fell apart. The problem revealed itself brutally in early 1942 when Royal Air Force squadrons started receiving their Mustangs below 15,000 ft. The aircraft was magnificent. RAF pilots used them for ground attack and reconnaissance missions, strafing German supply columns in France with devastating effect. But the moment you climbed above 15,000 ft, the Mustang transformed from a thoroughbred into a struggling cartor. The engine wheezed.

Acceleration died. In a high altitude dog fight against a Messersmidt BF- 109 or Faka Wolf FW90, the Mustang became a sitting duck. Pilots started calling it a lowaltitude sports car trapped in a high alitude war. The culprit was the Allison V1710 engine, a beautifully engineered piece of American machinery that had one fatal flaw. It used a single stage, singleseed supercharger. Let me break that down without turning this into an engineering lecture. At high altitude, air is thin.

There’s less oxygen for the engine to burn. A supercharger is essentially an air compressor that forces more oxygen into the engine cylinders. The Allison supercharger worked fine at sea level and medium altitude, delivering a respectable 150 horsepower. But above 15,000 ft, where most European air combat happened, that supercharger couldn’t compress enough air. Power dropped to around 900 horsepower. Meanwhile, German fighters with sophisticated two-stage superchargers maintained full power up to 25,000 ft. In a dog fight, horsepower equals options: speed, climb rate, the ability to escape or pursue.

The Mustang had beautiful aerodynamics, but not enough muscle to use them where it mattered. American pilots discovered this the hard way. The US Army Air Forces initially relegated their P-51s to low-level reconnaissance missions, essentially the same role the RAF had settled for. Photo reconnaissance Mustangs would scream across enemy territory at treetop level, using speed and surprise to avoid fighters rather than engaging them. It was humiliating for a plane that looked so promising. Engineers at Wrightfield in Ohio ran test after test, tweaking fuel mixtures and supercharger gearing.

But you can’t extract performance that isn’t there. The Allison simply wasn’t designed for high altitude combat. North American aviation’s brilliant airframe was being strangled by an underpowered heart. By mid 1942, the Mustang program looked like an expensive mistake. The army had ordered thousands of them. But what good was a fighter that couldn’t fight at bomber altitudes? B17 flying fortresses were getting slaughtered over Germany, losing dozens of aircraft per mission because their fighter escorts, P47 Thunderbolts and P38 Lightnings had to turn back before reaching deep targets.

The bombers would continue alone and Luftwaffa fighters would tear into them like wolves into sheep. Everyone knew the solution was a long range, high-altitude escort fighter. The Mustang had the range. It had the airframe, but it absolutely did not have the altitude performance. Schmood’s impossible design was dying of oxygen starvation. The solution came from an unlikely source, a British test pilot named Ronald Harker, who happened to visit North American Aviation’s Englewood factory in April 1942. Harker flew Spitfires for Rolls-Royce, testing engines and performance modifications.

When he climbed into a Mustang cockpit for a demonstration flight, he immediately recognized what American engineers had somehow missed. The airframe was extraordinary, better than anything he’d flown, but it was gasping for air at altitude. As soon as he landed, Harker sent a telegram to Rolls-Royce headquarters in Darby, England. Five words that would change the war. Flight testing Mustang needs Merlin engine. The Rolls-Royce Merlin wasn’t just any engine. It was the power plant that made Spitfires and Lancaster bombers legendary.

More importantly, it featured a two-stage, two-speed supercharger that maintained power up to 30,000 ft. The engineering was complex. The first supercharger stage compressed incoming air and intercooler reduced the temperature to increase density. Then the second stage compressed it again before forcing it into the cylinders. This setup produced 1,520 horsepower at 20,000 ft, nearly double what the Allison managed at that altitude. But swapping engines isn’t like changing a car battery. The Merlin was heavier, mounted differently, and required completely redesigned engine mounts, cooling systems, and propeller configurations.

Rolls-Royce didn’t wait for American approval. By October 1942, they’d pulled a Mustang from RAF inventory and shoehorned a Merlin 61 engine into it at their Hucknol facility. The first test flight happened on October 13th, 1942 with Rolls-Royce test pilot Captain Ronnie Shepard at the controls. Shepard climbed to 20,000 ft, expecting the usual sluggish response. Instead, the Mustang leapt forward like it had been unchained. He pushed it to 25,000 ft, still climbing strongly. At 30,000 ft, the engine was still pulling hard.

When he dove back down and opened the throttle, the airspeed indicator touched 433 mph. Shepard landed and filed a report that used words like phenomenal and revolutionary. The British immediately designated it the Mustang X and marked it top priority. Back in America, North American aviation and the Army Air Forces were scrambling to catch up. They’d been hearing rumors about the British Merlin tests, and in November 1942, Wrightfield received performance data that seemed too good to be true.

The numbers showed a 50 mph speed increase and a service ceiling jump from 31,000 ft to 41,900 ft. Some engineers suspected measurement errors. Then the first Americanbuilt Merlin Mustang designated XP51B took flight on November 30th, 1942 from Englewood. Test pilot Bob Chilton ran it through its paces and radioed down with barely contained excitement. This thing climbs like a homesick angel. The transformation was total. The same airframe that struggled above 15,000 ft now dominated at 25,000 ft and could fight effectively at 35,000 ft.

Packard Motor Company in Detroit started building Merlin engines under license, the Packard VI 1653, essentially an Americanbuilt Merlin with modified tooling for mass production. By early 1943, P-51B Mustangs with Merlin engines were rolling off assembly lines at both Englewood and a new factory in Dallas, Texas. The Allison engine Mustangs were quietly reassigned to ground attack and reconnaissance. The real Mustang, the one that would escort bombers to Berlin and back, had finally arrived. Schmood’s airframe had found its proper heart, and the Luftwaffa was about to discover what 1,500 horsepower combined with laminer flow wings could do in the hands of determined pilots.

Now, let’s talk about the actual magic that made Schmood’s design revolutionary, the wing. This is where most people’s eyes glaze over when engineers start throwing around terms like boundary layer and Reynolds numbers. But stick with me because this is the difference between a good fighter and a legendary one. Every aircraft wing drags air molecules along its surface as it flies. Normally, this creates turbulent air flow. Imagine tiny whirlpools and eddies swirling chaotically over the wing surface. Turbulent air means drag, and drag means you’re burning fuel just to fight the air itself.

Schmood needed to eliminate as much of that turbulence as possible. Enter the NACA 45100 series laminer flow air foil developed by engineer Eastman Jacobs at the Langley Research Center in Virginia during the late 1930s. Jacobs had spent years in wind tunnels studying how air moves over wing surfaces and he discovered something counterintuitive. Most aircraft wings of the 1930s had their thickest point about 25 to 30% back from the leading edge. Jacobs moved that maximum thickness point back to 45% almost halfway down the wing cord.

This subtle change created a different pressure gradient that kept air flow smooth and laminer, meaning the air molecules flowed in organized layers rather than chaotic turbulence for a much longer distance over the wing surface. The numbers were stunning. Wind tunnel tests showed that laminer flow wings could reduce drag by 30 to 40% compared to conventional air foils at cruise speeds. 30% less drag means you can fly the same distance on less fuel or carry more fuel and fly dramatically farther.

But, and this is critical, laminer flow only works if the wing surface is absolutely smooth. We’re talking imperfections measured in thousandth of an inch. A single rivet head sticking up, a bug splatter, even rough paint could trip the air flow from laminer to turbulent and destroy the advantage. Most engineers considered it impossible to maintain that precision in mass production, let alone in combat conditions with bullet holes and battlefield repairs. Schmood obsessed over manufacturing tolerances that seemed insane for 1940.

North American aviation developed flush riveting techniques where rivet heads sat perfectly flush with the wing skin rather than protruding. They used jigs and fixtures that held wing panels to tolerances of plus or minus 0.05 in. Workers hand sanded wing surfaces and applied multiple coats of primer and paint, wet sanding between each coat until the surface was glass smooth. Quality inspectors rejected wings that other manufacturers would have considered perfect. It added time and cost to production, but the results spoke for themselves.

The P-51’s internal fuel capacity was 269 gall, later increased to 489 gall with external drop tanks. That translated to an effective combat radius of 750 mi, meaning the Mustang could fly 750 mi, fight for 20 minutes, and return home. Compare that to a Spitfire Mark 9 with 85 gal internal fuel and a combat radius of barely 400 m or a P47 Thunderbolt with 305 g and a combat radius of 475 mi. The Mustang wasn’t just better, it was in a different category entirely.

And here’s the beautiful part. Because the laminer flow wing was so efficient at cruise speeds, the Mustang actually flew farther by flying faster. At 280 mph cruise speed, it consumed fuel so efficiently that adding external tanks turned it into a strategic weapon. Bomber crews started calling Mustangs little friends because for the first time in the air war over Europe, those little friends could stay with them all the way to the target and all the way home. March 4th, 1944.

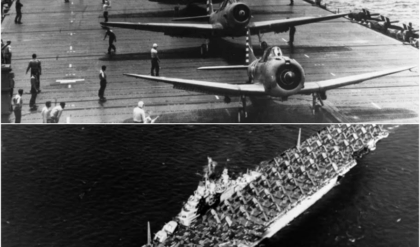

64 P-51B Mustangs from the fourth fighter group lifted off from Debbon Airfield in England at 10:15 in the morning, their wings heavy with 110galon drop tanks. The mission briefing had been blunt. Escort the B17 bombers to Berlin and bring them home. Berlin, Hitler’s capital, one 100 miles round trip deep in the heart of the Third Reich, where no Allied fighter had ever ventured. The bomber crews didn’t quite believe it. They’d watched too many escort fighters waggle their wings in apology and peel away at the German border, fuel gauges forcing them home, while Luftwaffa fighters moved in for the kill.

But this time would be different. Lieutenant Colonel Don Blakesley led the formation. A combat veteran who’d flown Spitfires with the RAF before transferring to American squadrons. Blakesley understood what this mission meant strategically. If Mustangs could reach Berlin, the Luftvafa had nowhere left to hide. German fighters had been retreating deeper into Reich territory, operating from bases they considered safe from American escorts. Berlin represented the psychological and practical heart of German air defense. If you could fight over Berlin, you could fight anywhere.

The weather was typical March misery. Thick clouds over the channel, icing conditions at altitude. Several Mustangs aborted with mechanical issues, but the main formation pressed on. They crossed into German airspace at 27,000 ft, throttled back to efficient cruise speed, nursing every gallon of fuel. The bomber stream stretched for miles, 316 B17s heading for a ballbearing factory inker, just outside Berlin. Around 11:40 near Brunswick, the first Luftwaffa fighters appeared. Messersmidt BF-109Gs and Faka Wolf FW19AS diving from above.

Normally this is where the escorts would already be gone, but today the Mustangs were still there and the German pilots hesitated. Years of habit told them American fighters shouldn’t be this far east. That hesitation cost them. The Mustangs broke formation and engaged, turning inside the German fighters, using their superior speed at altitude to dictate engagement terms. Captain Don Gentile shot down two MI 109s within 3 minutes, exploiting the Mustang’s climb rate to get above his opponents and use gravity assisted dives.

The laminer flow wings that Schmood had obsessed over let the Mustang maintain control at speeds where other fighters started buffeting and shaking. German pilots found themselves in the unfamiliar position of being outrun and outclimbed simultaneously. The furball, pilot slang for a tangled dog fight, scattered across 50 mi of German sky, but the critical fact remained. The bombers kept flying toward Berlin, and Mustangs kept protecting them. At 12:15, the formation crossed into Berlin’s airspace. Flack batteries opened up, filling the sky with black bursts of exploding shells.

But the weather worked in the allies favor. Cloud cover was so thick the anti-aircraft gunners were firing blind. The B17s dropped their bombs through the clouds using radar guidance and turned for home. The Mustang pilots checked their fuel gauges. They’d burned through the drop tanks and were into internal fuel, but the math still worked. The return leg would be flown at optimal cruise speed. No unnecessary maneuvering, straight lines home. By 14:30, the formation was back over the North Sea.

By 15 or wheels were touching down at English airfields. The mission statistics told the story. Five bombers lost mostly to flack. The Luftwaffa claimed 11 Mustangs destroyed, but actual losses were five, with three pilots rescued. American fighters claimed 13 German aircraft destroyed. But the real victory wasn’t the kill ratio. It was the psychological impact. Luftwafa pilots radioed their controllers in disbelief. American fighters over Berlin. Reich’s marshal Herman Guring, commander of the Luftwaffa, reportedly said, “When I saw Mustangs over Berlin, I knew the jig was up.” The myth of Fortress Germany had died at 27,000 ft, courtesy of Edgar Schmood’s impossible wing design, but reaching Berlin was only half the equation.

The Mustang also had to survive the fight once it got there. And this is where Schmood’s design philosophy paid dividends that nobody anticipated. German pilots in 1944 weren’t rookies. Many were aces with hundreds of combat hours, men who’d survived the Battle of Britain and the Eastern Front. They flew aircraft specifically engineered for high altitude interception. The Messers BF 109G could hit 400 mph and climb at 3,100 ft per minute. The Fauly Wolf FW190A was even more formidable.

a brutish radial engine fighter that could absorb tremendous punishment and roll faster than anything in the sky. On paper, these were peer competitors. In practice, the Mustang made experienced German pilots look like students. The P-51D, which entered service in mid 1944 with a bubble canopy for 360° visibility, topped out at 437 mph at 25,000 ft. That’s fast, but not overwhelmingly faster than German fighters. The real advantage was climb rate, 3,200 ft per minute. With the Merlin engine roaring at war emergency power in a dog fight, whoever gets above the enemy first controls the fight, you

can dive down with gravity adding to your speed, choose when to engage, and break off by climbing away if things go wrong. German pilots found that Mustangs could climb with them, then keep climbing when their own engines started gasping for air. The two-stage Merlin supercharger was simply breathing better at 28,000 ft than anything the Luftwaffa fielded. Turn performance separated good fighters from great ones, and here the laminer flow wing delivered again. The Mustang could sustain a turn radius of roughly 1,200 ft at 300 mph without bleeding excessive energy, meaning it could whip around in a tight circle while maintaining speed.

The FW190 turned wider. The BF 109 could turn tighter initially, but bled speed rapidly, leaving the pilot vulnerable. American pilots learned to exploit this. If a Messor Schmidt got on your tail, you’d pull into a climbing spiral turn. The 109 would follow. Both aircraft pulling maybe four or 5 G’s, enough to gray out your vision at the edges. But the Mustang maintained its energy state better. After two full turns, the 109 would be wallowing, slow, and vulnerable.

While the Mustang still had knots in reserve to reverse the fight, diving speed mattered enormously when things went wrong. The Mustang was cleared for dives up to 505 mph, though pilots regularly exceeded that chasing fleeing German jets. The airframe stayed solid. No wing flutter, no control lockup. Schmood had designed structural strength into every component using stressed skin construction where the aluminum skin itself carried aerodynamic loads rather than relying solely on internal frameworks. German fighters, particularly the 109, had issues with elevator flutter in high-speed dives.

Pilots learned to be cautious, pushing past 450 mph. That 50 mph difference meant a diving Mustang could catch almost any fleeing opponent or escape almost any pursuer. Firepower sealed the deal. The P-51D carried six 50 caliber Browning M2 machine guns, three per wing, with 1,80 rounds total. Each gun fired 800 rounds per minute, and at convergence range, typically set for 300 yards, all six streams of bullets met in a cone of destruction about 6 ft across. A two-cond burst put roughly 160 bullets into that cone against the relatively fragile structure of German fighters.

That was devastating. Pilots reported seeing wings fold, tails separate, and cockpits disintegrate under concentrated 50 caliber fire. The Mustang wasn’t just faster and more maneuverable. It hit harder. German aces who’d survived years of combat found themselves outmatched by American pilots with 50 hours of combat time simply because the Mustang gave those rookies tools to compensate for inexperience. That’s the hallmark of truly great engineering. It makes the difficult look easy. Let’s talk about what happened when you deployed thousands of these aircraft with pilots who’d been told their primary job wasn’t shooting down enemy fighters.

It was bringing the bombers home. That doctrinal shift combined with the Mustangs capabilities created a statistical massacre. Between January 1944 and May 1945, P-51 Mustangs were credited with destroying 4,50 enemy aircraft, more than any other Allied fighter in the European theater. That number includes 4,131 aircraft shot down in air combat and another 819 destroyed on the ground during strafing runs. But raw kill numbers only tell part of the story. You have to look at what those kills accomplished strategically.

The Eighth Air Force, the primary American bomber force in England, lost 350 heavy bombers per month on average during the second half of 1943. That’s roughly 3,500 trained air crew killed or captured every 30 days, unsustainable by any measure. Each B17 or B-24 carried 10 men, represented hundreds of thousands of dollars in manufacturing costs, and required months of crew training. The Luftwaffa was winning the attrition war simply by forcing unescorted bombers to run a gauntlet of fighters concentrated at choke points along the route to German industrial targets.

In October 1943, a raid on Schweine Fort lost 60 bombers out of 291 dispatched, a 20% loss rate that would bankrupt the entire bombing campaign within months if it continued. The arrival of long range P-51B escorts in December 1943 changed the math immediately. By March 1944, bomber loss rates had dropped to 3.5% per mission. By June 1944, after D-Day, when Mustang groups were flying multiple daily missions, the rate fell below 2%. The Luftwaffa didn’t suddenly get worse at fighting.

They got forced into an impossible situation. German fighters had to engage the bombers to stop the destruction of Reich industry. But engaging meant running through a screen of Mustangs that could chase them anywhere. Luftwaffa pilots started reporting situations where they’d spot bomber formations but couldn’t attack because Mustangs held the altitude advantage. The escorts had shifted from defensive to offensive operations. Ground attack missions added another dimension of destruction. Once bomber formations were safely on course home, Mustang squadrons would descend to treetop level and hunt targets of opportunity.

locomotives, trucks, fuel depots, aircraft parked on airfields. The 50 caliber guns that could shred a fighter at altitude proved equally effective against thin skinned ground targets. German train engineers learned to abandon their locomotives the moment they saw Mustangs approaching because a single strafing pass could turn a steam engine into scrap metal. Luftwaffa airfields moved aircraft into blast proof revetments and scattered them across multiple satellite fields, but that just made maintenance and operations more difficult. The Mustang forced the entire German air defense system into reactive mode.

The cost wasn’t trivial. The Eighth Air Force lost approximately 2,520 P-51s between 1943 and 1945 with roughly 1300 pilots killed. That’s a loss rate of about 33% against enemy aircraft destroyed, a favorable exchange ratio, but still painful. Many losses came from flack and ground fire during low-level strafing runs, the most dangerous mission profile. A single rifle bullet through the radiator could doom a Mustang by causing coolant loss and engine failure. But the strategic calculus was brutal and clear.

Trading one highly trained fighter pilot for two or three German fighters, plus saving dozens of bomber crew lives was mathematically necessary to win the war. By spring 1945, the Luftwaffa had been ground down to a shadow force, operating sporadically with inadequate fuel and green pilots who had maybe 30 hours of flight training. The Mustang hadn’t single-handedly won air superiority, but it had made victory inevitable and accelerated it by months. The war ended in May 1945 and most wartime aircraft designs vanished into scrapyards or museums within a few years.

The future belonged to jets. Everyone knew that. The Messormidt Mi262 jet fighter had already proven that piston engines were obsolete even if it arrived too late to save Germany. Yet Edgar Schmood’s Mustang refused to retire gracefully. The design principles embedded in that laminer flow wing and stressed skin fuselage kept finding new applications long after the last combat mission over Europe. The story of what happened next reveals something important about truly revolutionary engineering. Great design transcends its original purpose.

The Korean War broke out in June 1950, and suddenly the Air Force needed ground attack aircraft that could operate from rough forward air strips and survive heavy anti-aircraft fire. Jets of that era were temperamental, fuel- hungry, and required long concrete runways. The F-51D Mustang, redesated when the Air Force became independent in 1947, came out of mothballs and deployed to Korea within weeks. Pilots found that the aircraft performed ground attack missions superbly, carrying bombs, rockets, and napalm while absorbing battle damage that would down a jet.

The reliable Merlin engine and robust airframe meant Mustangs could operate from primitive strips near the front lines. They flew 62 607 combat sorties in Korea, losing 351 aircraft primarily to ground fire. Not bad for a design that was already a decade old. But the most surprising longevity came in foreign service. Smaller nations couldn’t afford jet fighters or the infrastructure to maintain them. but they could operate Mustangs effectively with minimal support. The Israeli Air Force flew P-51Ds during the 1948 Arab-Israeli War and kept them in service until 1961.

The Dominican Air Force operated Mustangs until 1984. Yes, 1984, 44 years after the prototype first flew. These weren’t museum pieces doing air show demonstrations. They were operational combat aircraft flying border patrol and counterinsurgency missions. The simple fact that third world air forces could maintain complex Merlin engines with limited part supplies speaks to how well engineered the entire package was. Schmood himself moved on to other projects. After the war, he joined North American’s jet programs and became chief designer for the F86 Saber, the sweptwing fighter that dominated MiG 15s over Korea.

If you look closely at the F86’s design philosophy, you can see Mustang DNA, emphasis on pilot visibility, efficient aerodynamics, and range. The Saber wasn’t just a Mustang with a jet engine, but it inherited the same obsessive attention to drag reduction and structural efficiency. Schmood retired in 1960 and died in 1985, having lived long enough to see his impossible 1940 design, still flying in combat four decades later. Not many engineers get to witness that kind of legacy. The technical influence went deeper than individual aircraft.

The NACA 45100 laminer flow air foil that Schmood bet his career on became the foundation for research into superc critical wings used on modern airliners. Engineers studying transonic flight in the 1960s realized that laminer flow principles could delay shock wave formation at high subsonic speeds. Boeing applied these lessons to the 737 and 747. Airbus used similar concepts on the A320 family. Every time you board a commercial airliner with long range and fuel efficiency, you’re benefiting from aerodynamic principles that Edgar Schmood proved could work not just in wind tunnels, but in combat at 400 mph with someone shooting at you.

The P-51 Mustang proved something that military procurement offices still struggle to accept. Sometimes the best solution comes from an engineer nobody asked. Solving a problem in ways nobody expected on a timeline nobody believed possible. Schmood’s 120day impossible deadline in 1940 produced an aircraft that influenced aerospace design for three generations. That’s not just good engineering. That’s vision executed with precision under impossible pressure. The bombers made it to Berlin and back because one German immigrant refused to accept that physics had already decided what was possible.