August 17th, 1944. Northern France near Files. The GMC CCCKW sat abandoned on the roadside, its canvas cover torn by shrapnel, engines still warm. The American convoy it belonged to had been caught in a Luftvafa strafing run, one of the increasingly rare occasions when German aircraft actually appeared over France. Vermacharked mechanics from the 276th Infantry Division approached cautiously, examining what the Americans called a deuce and a half. “Get the hopfeld Weeble,” one mechanic called. “This one’s intact.” “What they discovered over the next hour would confirm suspicions that had been growing since Normandy.” Germany had already lost this war, not on the battlefield, but in the factories of Detroit.

The truck was massive compared to German vehicles at 2 1/2 tons rated capacity. It dwarfed the standard Opal Blitz. Yet, the mechanics immediately noticed something unexpected. It wasn’t complicated. The six-cylinder engine sat openly accessible with parts clearly labeled in English. The mechanic opened the toolbox mounted on the running board. Inside were standard wrenches, pliers, and a manual printed on quality paper with detailed illustrations. “Look at this,” the Hedfeld Weeble said, flipping through the manual. “Everything is explained with pictures.

A child could follow these instructions.” “They had captured American trucks before, but never examined one so thoroughly. The GMC bore markings indicating it was a 1943 model CCKW353, the long wheelbase version. Production number stamps showed it was one of thousands built that year at the Pontiac plant. Thousands from a single factory. The first mechanical inspection revealed the philosophy. The GMC 270 engine produced 104 horsepower from 269 cub in. Not impressive by German standards. But the mechanic recognized immediately that performance wasn’t the goal.

Every bolt was the same size. Every nut could be turned with the same wrench. The spark plugs were positioned for easy access. The oil filter could be changed without tools. This is designed for idiots, one mechanic muttered. The hoppedfeld weeble corrected him. No, it’s designed for an army of millions where most men aren’t mechanics. This is brilliant. He was right. The GMC wasn’t engineered for perfection. It was engineered for America’s conscript army, where farm boys from Iowa and factory workers from Pennsylvania would become combat drivers with minimal training.

Every component was selected for availability and ease of replacement. Nothing was exotic. Nothing required specialty knowledge. They examined the six-wheel drive system. A simple transfer case engaged the front axle with a single lever. In comparison, their Opal Blitz trucks were rearwheel drive only, struggling constantly in French mud and requiring careful driving to avoid getting stuck. This American truck could power through terrain that would immobilize German vehicles. The suspension used basic leaf springs, crude but unbreakable. The Hopfeld Weeble thought of the sophisticated torsion bar suspension on the opal.

Beautiful engineering that required factory tools to repair. These leaf springs could be hammered straight with a rock if necessary. Most troubling was what the numbers revealed. Stamped into the frame was Pontiac plant number one. The production number indicated this truck was one of approximately 150,000 built in 1943 alone. One plant, one year, more trucks than Germany produced in all categories combined. One mechanic did the math. If one American plant produces this many trucks, how many plants do they have?

The answer was dozens. GMC, Chevrolet, Studebaker, International Harvester, Dodge, Ford, all producing similar vehicles to standardized military specifications, all with interchangeable parts. That evening, the unit’s supply officer joined the inspection. He had worked in the Opal plant in Brandenburgg before the war, understanding automotive manufacturing deeply. “We’re looking at this wrong,” he said. “We see a simple truck, but what this represents is an entire manufacturing philosophy we can’t match.” He explained what the GMC revealed about American production.

The stamped steel body panels were crude, but could be produced in vast quantities by any press shop. The wooden cargo bed used standard lumber that any sawmill could provide. The canvas top was commercial fabric. Nothing was specialized. Everything was abundant. Look at the chassis, he continued, pointing to the ladder frame. Straight channel steel welded together. Any structural steel plant could produce these. Compare that to our Opel with its precisely formed frame rails requiring specialized dyes. The Americans had designed for their strength, massive industrial capacity.

The GMC wasn’t superior to the Opal Blitz in engineering elegance. But it was superior in the metric that mattered, producability. The supply officer’s assessment grew darker. In 1943, we produced approximately 27,000 Opal Blitz trucks. The Americans probably built 20 times that number of these GMC trucks alone. And that’s just one truck type from one manufacturer. He was understating it. American factories would produce over 562,000 CCKW trucks during the war. Germany’s entire wartime production of the Opal Blitz, the backbone of Vermachar Logistics, totaled perhaps 100,000 units, most being the 4×2 version that lacked the GMC’s all-wheel drive capability.

Over the next week, the unit used the captured GMC for supply runs. It transformed their capabilities. where their opal trucks struggled through muddy farm roads, the GMC simply powered through. When loaded beyond its rated capacity, something that happened constantly, it continued functioning. The six-wheel drive provided traction that their rearwheel drive vehicles couldn’t match. A supply sergeant who drove it daily offered his assessment. This truck is reliable in a way our vehicles aren’t. It’s not that it’s better built.

It’s that it’s built expecting abuse. They designed it knowing soldiers would overload it, neglect maintenance, and drive it like they’re trying to destroy it. That was the revelation. American engineers had designed the GMC for the reality of war, not the theory of it. They assumed drivers would be poorly trained, maintenance would be delayed, and operating conditions would be terrible. So they built accordingly. Simple, robust, forgiving. On August 25th, 1944, the same day the Red Ball Express began operations, the 276th Infantry Division received orders to withdraw eastward.

They witnessed something that completed their education in American logistics. An American convoy passed on a parallel road, not a tactical movement, but a supply column. The watching Germans counted vehicles as they rolled past. After half an hour, they gave up counting. Truck after truck after truck, stretching to the horizon. GMC CCKW trucks predominated, all identical, all loaded with supplies, all moving with mechanical precision toward the front. “Where are their horses?” a young soldier asked, genuinely confused. “The Hopedfeld Weeble realized the boy had never seen a fully motorized army.

In the Vermacht, 80% of logistics relied on horses. Their division alone required over 5,000 horses to move supplies. Those horses needed food, water, rest, and veterinary care. They could march perhaps 30 kilometers per day in good conditions. They died by the thousands in winter. American divisions had no horses. They had trucks. Thousands of trucks that could move hundreds of kilometers per day required no fodder, didn’t tire, and didn’t freeze to death. The supply officer did more calculations that night.

Each American division has approximately 2,000 trucks. They have 40 divisions in France. That’s 80,000 trucks supporting combat operations, not counting the supply services. We have 3 million horses total across all fronts and maybe 100,000 trucks. Someone asked the obvious question, how can they produce so many vehicles? The answer was painful to articulate. American automotive plants had been designed for mass production long before the war. Ford’s assembly line, GM’s production systems. When war came, they simply converted civilian production to military needs.

The same factories that built Chevrolet sedans built GMC trucks. The same workers who assembled Oldsmobiles assembled military vehicles. The transition was seamless because the manufacturing philosophy was identical. Standardization, interchangeability, mass production. Germany had excellent engineers but lacked this production infrastructure. The Opel plant in Brandenburgg, even at peak production, couldn’t match a single American automotive complex. And America had dozens of such complexes. By September 1944, the unit had captured three more GMC trucks and a Dodge WC63. The mechanics noticed something remarkable.

Parts were interchangeable not just between GMC trucks, but between different manufacturers. A GMC carburetor fit the Dodge. Electrical components were standardized. Even tires were the same size. They’ve standardized their entire vehicle fleet, the supply officer explained. One set of specifications, multiple manufacturers. It means any mechanic can service any truck, any parts depot can supply any vehicle. Their logistics are unified in a way ours have never been. The Vermacht used vehicles from dozens of manufacturers with incompatible parts.

A mechanic trained on an Opal couldn’t necessarily service a Booing or a Mercedes. Parts warehouses had to stock components for hundreds of vehicle types. It was a logistical nightmare. On October 3rd, 1944, the division’s remaining vehicles became stranded when fuel supplies failed to arrive. The horses could forage, but the trucks sat immobile. Meanwhile, American operations continued unabated because their supply network, built on thousands of GMC trucks, delivered fuel reliably to forward units. The mechanics spent their enforced idleness studying the captured American trucks.

One made an observation that crystallized their understanding. We designed our vehicles to be good. They designed theirs to be good enough, but in overwhelming numbers in total war that wins. The Hedfeld Weeble wrote a detailed technical report on the GMC CCKW. It documented every aspect, the standardized components, the simple maintenance procedures, the robust construction that sacrificed elegance for durability. The report noted that while the Opel Blitz was superior to the GMC in fuel efficiency and maneuverability, these advantages were meaningless when Germany produced one truck for every five or six American trucks.

The report concluded, “American vehicle production represents industrial capacity we cannot match. Their manufacturing philosophy prioritizes quantity and standardization over individual vehicle perfection. In sustained warfare, this approach has proven devastatingly effective.” Similar reports were flooding Vermacharked headquarters from every front. German intelligence analysts compiled American production statistics with growing alarm. The numbers were staggering. American factories produced 2.4 million military trucks during the war. Germany, Italy, and Japan combined couldn’t approach that total. December 1944 brought the Arden’s offensive, Hitler’s last gamble in the West.

The operation’s logistics plan relied heavily on capturing American fuel supplies because Germany lacked sufficient fuel to sustain the offensive. German soldiers were ordered to use captured American vehicles whenever possible because German logistics couldn’t keep pace. The irony was bitter. Germany’s last major offensive depended on capturing the very vehicles and fuel that symbolized why Germany was losing. The 276th Infantry Division participated in the offensive using their collection of captured American trucks alongside their few remaining Opal vehicles. When the offensive stalled, it wasn’t primarily because of American resistance, though that was fierce, but because German logistics collapsed.

Panzer divisions abandoned tanks when fuel trucks couldn’t reach them. Infantry units resorted to horsedrawn wagons because motorized transport had broken down. Meanwhile, American supply operations continued with mechanical efficiency. The Red Ball Express had ended in November, but American logistics now operated from Antwerp, Brussels, and Sherborg. Trucks moved supplies on routes that became more efficient as engineers rebuilt French infrastructure. The American army was a machine fed by industry operating at a scale Germany had never achieved. In January 1945, as the Arden’s offensive failed and German forces retreated, the captured GMC trucks proved invaluable.

They still ran. The Opal trucks, subjected to the same harsh conditions, had mostly broken down. The difference wasn’t just maintenance. It was design philosophy. The GMC was built to absorb punishment. The Opel was built to German standards of precision that couldn’t tolerate wartime abuse. By March 1945, the 276th Infantry Division was defending positions in the Rhineland. American forces had crossed the Rine in overwhelming strength. The mechanics watched American supply operations with professional admiration tinged with despair. They’ve built an army that runs on logistics, and they’ve built logistics that can’t be stopped, the Hopfeld Weeble observed.

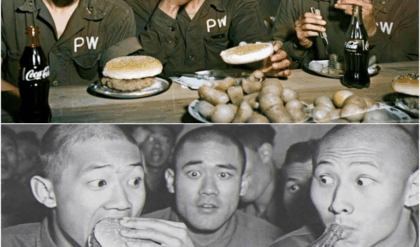

Our army was built assuming we’d fight short campaigns where tactical excellence would overcome material disadvantages. We never planned for this. years of sustained combat against an enemy that produces equipment faster than we can destroy it. The division surrendered on April 18th, 1945. They became prisoners transported to processing centers in American GMC trucks. The journey provided a final education in American industrial capacity. At the processing center near Cooblance, prisoners saw hundreds of American trucks in motor pools. Young American soldiers serviced them with casual efficiency that would have been impossible in the Vermacht.

Parts were abundant. Tools were readily available. Maintenance manuals were simple enough that soldiers with minimal training could perform complex repairs. A captured mechanic spoke with an American motor sergeant who was surprisingly friendly given the circumstances. Your mechanics? Hell, we need mechanics. Can you work on these? The sergeant gestured at the GMC trucks. Yes, we’ve maintained several captured ones. Good. The war is over for you guys, but these trucks still need maintenance. I can get you assigned to the motorpool.

Better than sitting behind wire. Over the following weeks, German mechanics worked alongside American soldiers, maintaining the very vehicles that had helped defeat them. The American sergeant explained the maintenance philosophy with unguarded honesty. We design everything for speed, quick maintenance, common parts, simple procedures. See this engine? Complete overhaul can be done by a twoman team in 8 hours using field tools. Try doing that with one of your trucks. The German mechanic acknowledged the truth. An Opal engine overhaul requires factory conditions and specialized equipment.

We designed for precision. You designed for practicality. Exactly. In peace time, your way probably produces better vehicles. In war, our way produces vehicles that keep armies moving. How many of these GMC trucks you think we built? I don’t know. Hundreds of thousands. Over half a million of just this model. Then there’s the Dodges, the Studebakers, the Internationals. Millions of trucks total. That’s what won the war. Not better equipment, but more equipment than you could ever destroy. The American continued.

You know what’s funny? These trucks aren’t that complicated. We used commercial truck technology, barely modified it for military use, the engines a commercial design, the transmissions commercial. We just made it rugged and produced it in massive quantities. This was the lesson German mechanics absorbed completely. America had won through industrial philosophy as much as industrial capacity. They designed for mass production from the start, standardized ruthlessly, prioritized reliability over sophistication, and built supply chains that could sustain operations indefinitely.

The mechanics spent months in prisoner camps, many working in American motor pools. They witnessed the scale of American logistics daily. Convoys of hundreds of trucks moving supplies across occupied Germany. Repair depots with more spare parts than entire German divisions had possessed. Production systems so efficient that damaged vehicles were often replaced rather than repaired because new vehicles arrived faster than repairs could be completed. In late 1945, as repatriation began, German mechanics returned to a devastated homeland. Cities were rubble, factories were destroyed, but everywhere were American vehicles, GMC trucks hauling reconstruction materials, jeeps carrying occupation forces, equipment supporting the beginning of German rebuilding.

The HPfeld Wayel, now just a civilian, found work at a reconstruction depot in Frankfurt. His experience with American vehicles made him valuable. One day, training young Germans in vehicle maintenance, he reflected on what the war had taught him. Before the war, we believed German engineering was superior, that quality would overcome quantity. We were wrong. The Americans understood modern industrial warfare better than we did. They built adequate equipment in overwhelming numbers. They standardized ruthlessly. They designed for the army.

They had millions of ordinary men, not the army we wished we had. Elite specialists, he gestured at the GMC trucks in the depot yard. These trucks aren’t masterpieces of engineering, but they won the war because there were hundreds of thousands of them. They all used the same parts. Any soldier could drive them, and any mechanic could fix them. That was the genius. Not in individual vehicles, but in the system that produced them. By 1947, the Marshall Plan was delivering aid to Germany, transported primarily in American trucks.

German mechanics maintained these vehicles, applying lessons learned from years of observation and practice. When German industry began rebuilding, many incorporated American manufacturing principles, standardization, component commonality, design for manufacturability. The GMC CCKW remained in American service until the 1960s, a testament to its robust design. Many served even longer in Allied militaries. The Opel Blitz, despite being an excellent vehicle, had become a symbol of Germany’s industrial shortcomings during the war. In the decades that followed, German automotive manufacturers merged German engineering precision with American mass production techniques.

Companies like MercedesBenz, BMW, and rebuilt Volkswagen created vehicles that combined both philosophies. Precision engineering designed for efficient mass production. Former Vermacharked mechanics who had maintained both German and American vehicles during the war became valuable consultants to rebuilding German industry. They understood both approaches and could articulate why the American system had proven superior in sustained conflict. One such consultant in a 1967 interview for an automotive trade journal summarized the lesson. The GMC truck taught us that in modern warfare, perfection is the enemy of good enough.

Germany designed beautiful vehicles that were too complex to produce in necessary quantities and too sophisticated for field maintenance. America designed adequate vehicles that could be produced by the millions and maintained by anyone. We lost not because our engineers were inferior, but because we misunderstood what industrial warfare required. The article included a photograph of a restored GMC CCKW at an automotive museum. The caption read, “American GMC CCKW deuce and a half truck. Over 560,000 produced 1941 to 1945.

These trucks formed the backbone of the Red Ball Express and represented the American industrial philosophy that overwhelmed Axis powers through mass production and standardization. Beside it, for comparison, sat a restored Opel Blitz. The caption, German Opel Blitz, 3-tonon truck, approximately 100,000 produced 1937 to 1944. Excellent vehicle design hampered by limited production capacity and lack of four-wheel drive in most models. The visual comparison told the story completely. Both were well-designed trucks, but one existed in overwhelming numbers with standardized parts, simple maintenance, and a supporting logistics network that could sustain armies indefinitely.

The other was a quality product produced in insufficient quantities by an industrial base that couldn’t compete with American manufacturing capacity. The mechanics who examined that first captured GMC in August 1944 had understood immediately what it represented. They had seen the future and Germany’s past. American industrial philosophy developed in the automotive plants of Detroit and refined through decades of mass production had proven itself the superior approach for modern warfare. The GMC CCKW wasn’t just a truck. It was a teacher of hard lessons about industrial warfare, about design philosophy, and about why quantity has a quality all its own.

For German mechanics who maintained these vehicles as prisoners and later as civilians helping rebuild their country, those lessons shaped the rest of their lives and influenced German manufacturing for generations. The story of Vermacharked mechanics and the GMC truck is ultimately about learning through defeat. They had believed in German superiority, in precision over quantity, in engineering perfection over mass production. American trucks, simple, abundant, reliable, taught them otherwise. That knowledge, painful in acquisition, became invaluable in reconstruction, helping transform Germany from a defeated enemy to a prosperous ally built on lessons learned from thousands of American trucks that had rolled through European battlefields.

The mechanics who drove captured GMC trucks admitted they had never had vehicles quite like them, not because of superior engineering, but because of a production philosophy Germany had never mastered. That admission, honest and humbling, marked the beginning of wisdom that rebuilt a nation.