How One Mechanic’s “OUTLAWED” Idea Created America’s Navy’s Fastest Warship

April 14th, 1942. Brooklyn Navyyard, dry dock number three. The welding torch in Frank Genevvesy’s hand trembled slightly as he prepared to make a modification that could end his career. Get him court marshaled or possibly revolutionize naval warfare. The destroyer escort USS Buckley sat in dry dock halfway through construction, its hull plates gleaming under the harsh worklights of the graveyard shift.

Genevves, a 43-year-old chief machinist mate who had joined the Navy in 1917 and spent 25 years maintaining steam turbines, stared at the propeller shaft assembly that every naval architect, every marine engineer, every Bureau of Ship specifications said was the only correct design. The specifications were wrong. He knew they were wrong.

And tonight, with his shift supervisor absent and the bureau inspectors not due until Monday, he was going to prove it. The modification he planned violated three direct orders from the Bureau of Ships, contradicted two decades of accepted naval architecture, and if it failed, would likely sink the ship on its maiden voyage.

If it succeeded, it might make the Buckley the fastest destroyer escort in the United States Navy, possibly the fastest warship of its size in the world. Genevies looked at the technical drawings spread across the workt. Official Bureau of Ships plans showing the standard propeller shaft arrangement used on every destroyer escort in the American fleet.

Reliable, proven, conventional, and in Genevy’s professional opinion, fundamentally inefficient in ways that cost American ships 10 to 15% of their potential speed. He pulled out a second set of drawings from his tool bag, unofficial sketches he had worked on for years, modifications he had proposed through proper channels in 1938 and 1941.

Each time the Bureau of Ships had rejected his proposals, a machinist made suggesting modifications to propeller design was like a janitor suggesting modifications to Einstein’s relativity equations. Naval architecture was the province of Annapapolis graduates and civilian engineers with advanced degrees, not enlisted men who worked with their hands.

But Frank Genevvesi had spent 25 years listening to ship propellers. He had maintained the drive systems on destroyers, cruisers, and battleships. He had heard the subtle sounds that indicated cavitation, the formation of vapor bubbles that reduced propeller efficiency. He had calculated using slide rule and notebook that American warships were losing significant speed to design features that naval architects considered essential.

The specific problem was the shaft struts, the underwater supports that held the propeller shafts in alignment. Standard naval architecture placed these struts directly ahead of the propellers in positions that created turbulent water flow. The turbulence reduced propeller efficiency. Every ship in the fleet had this problem. Every navy in the world used similar designs.

It was considered unavoidable. Genevies believed he could eliminate 90% of the turbulence by repositioning the struts and modifying their shape. His calculations suggested this could increase top speed by 2 to three knots, improve fuel efficiency by 8 to 10%, and reduce mechanical stress on the entire drivetrain.

For a destroyer escort, three knots meant the difference between catching a submarine and letting it escape. He had tried to explain this to officers. They had nodded politely and ignored him. He had submitted formal proposals. They had been rejected with form letters. He had built scale models and conducted his own testing in the Navy yards testing tank after hours without authorization.

The results confirmed his calculations. The modified design worked better than the standard design, but no one with authority to approve changes cared about the observations of an enlisted machinist until tonight. Tonight, Frank Genevvesi was going to modify the USS Buckley’s propeller shaft assembly according to his unauthorized design.

He was going to commit what the Navy would consider sabotage because Genevves knew something that the officers didn’t know. The Battle of the Atlantic was being lost. and it was being lost because American destroyers and destroyer escorts couldn’t catch German submarines. The mathematics were brutal. German type 7 Ubot could make 17 knots on the surface.

American destroyer escorts had a design speed of 23 knots. That should have been enough, but in practice, loaded with fuel and ammunition in rough Atlantic weather, the destroyer escorts rarely made more than 19 knots. The speed margin was too narrow. Submarines detected early enough could dive and escape. Every knot of additional speed meant more submarines caught, more convoys protected, more merchant ships saved.

Three additional knots could change the balance of the Battle of the Atlantic. It was worth risking his career. It was worth risking court marshall. Genevves began cutting away the standard strut assemblies, working quickly but carefully. Each cut was irreversible. By 0400 hours, there would be no way to hide what he had done. By 0600 hours, when the day shift arrived, the modification would be complete and the ship would be committed to his design.

What Genevves didn’t know was that his unauthorized modification would trigger a chain of events that would transform American naval architecture and ultimately create not just one fast ship, but an entire class of warships that would dominate naval warfare for decades. This is the story of the idea that was outlawed, the man who implemented it anyway, and the fastest warship that resulted.

The crisis in the Atlantic was worse than the American public knew. By April 1942, German yubot had sunk over 800 Allied merchant ships totaling more than 4 million tons. The rate of sinking exceeded the rate of ship construction by a factor of three. Britain was being slowly strangled. The entire Allied strategy depended on winning the Battle of the Atlantic.

American destroyer escorts were supposed to solve this problem. The Navy had ordered over 500 of them. But there was a problem. The destroyer escorts weren’t fast enough. Admiral Ernest King, Chief of Naval Operations, received regular reports about submarines escaping from destroyer escorts. The pattern was consistent. Radar would detect a surfaced submarine.

The destroyer escort would pursue. The submarine would run at 17 knots. The destroyer escort, struggling to make 20 knots in Atlantic weather, would slowly close the range. Before closing to gun range, the submarine would dive and escape. King’s staff calculated that if destroyer escorts could make 26 knots reliably, the submarines couldn’t escape.

But the destroyer escorts couldn’t make 26 knots. The Bureau of Ships responded that increasing speed required larger engines, bigger hulls, longer construction time. The specifications were correct. Nothing could be done. This was the institutional response that Frank Genevvesy’s modification would challenge.

On April 15th, 1942, at 0600 hours, the dayshift supervisor at Brooklyn Navy Yard, Robert Henderson, discovered that the USS Buckley’s propeller shaft assemblies had been completely rebuilt overnight according to a design that didn’t match bureau specifications. His first reaction was to assume sabotage. But there was a problem.

Genevvesi had cut away the original strut mounting points. Restoring the standard design would delay the ship’s completion by at least 6 weeks. Every day of delay meant convoys sailing with one less escort. Henderson examined Genevese’s calculations. The mathematics were crude, but they weren’t wrong. Henderson, who had a master’s degree in marine engineering from MIT, could see that Genevvesi had intuitively grasped principles normally taught using advanced calculus.

The proposed strut positions would reduce turbulence. The design might actually work. Henderson made a decision that violated every regulation. He certified that the Buckley’s propeller assemblies were built according to specification. This was a lie. He documented the actual design in a separate technical report that he filed without sending to Washington.

He told Genevy that if the ship’s sea trials showed any problems, Henderson would claim he had been deceived and Genevy would face court marshall alone. The USS Buckley was launched on May 9th, 1942. No one except Henderson and Genevies knew that the ship’s propeller assemblies were non-standard. Sea trials were scheduled for June 1st.

Genevves found himself assigned to the Buckley’s crew as chief machinist mate. If the modification failed, Genevves would be aboard when it happened. June 1st, 1942, the Buckley began speed trials. The protocol called for progressive increases in power, measuring speed at each level. Every destroyer escort of the Buckley’s class had gone through identical trials.

At 80% power, ships made 18 to 19 knots. At 90% power, 20 to 21 knots. At 100% power, 22 to 23 knots. At 80% power, the Buckley made 19.2 knots normal. At 90% power, 21.4 knots. Slightly better than average. At 100% power, the Buckley made 24.8 knots. This was impossible. The trial observers checked their instruments.

The speed was confirmed by multiple methods. The Buckley was making nearly 25 knots, one and a half knots faster than any ship of its class had ever achieved. The Bureau of Ship’s observer on board, Commander Thomas Harrison, demanded an explanation. The ship’s engineering officer had no explanation. The ship was simply faster than it should be.

Harrison ordered additional runs. Every run confirmed the result. The Buckley could make 25 knots reliably. Henderson watched Harrison’s face go through shock, confusion, and suspicion. Harrison began asking questions about modifications. Henderson claimed ignorance. Perhaps the engines were exceptional.

Perhaps this was just a very good ship. Harrison didn’t believe it, but he had no evidence of unauthorized modifications. He filed his report noting exceptional performance and recommending investigation. If you’re fascinated by these stories of American ingenuity and how ordinary people changed history, make sure to subscribe to our channel and hit that notification bell.

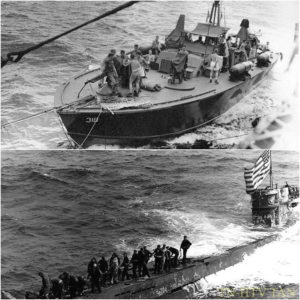

We bring you the untold stories of innovation and rulebreaking that shaped our world. Now, let’s continue with how Genevese’s modification transformed the entire Navy. The USS Buckley departed for the Atlantic on July 2nd, 1942. Her first convoy escort mission was designated on 113. On July 9th at 2200 hours, the Buckley’s radar detected a surfaced submarine at 16,000 yards south of the convoy.

The contact was Yubot 401 under command of Capitan Lieutenant Wolf Gang Barts. Barts chose to run. German doctrine was to exploit the limited speed advantage to escape when detected at long range. Yuboat 401 could make 17 knots. Allied destroyer escorts averaged 19 to 20 knots in pursuit. At 16,000 yds range, the submarine would have 20 minutes to gain distance before diving.

It was a proven escape technique, but the Buckley wasn’t a standard destroyer escort. At 25 knots, the Buckley closed at 8 knots relative speed rather than 2 to three knots. Barts couldn’t believe his calculations. The destroyer escort was moving far faster than intelligence said was possible.

After 15 minutes, with range closing to 8,000 yd, BARTs ordered emergency dive. Yubot 401 survived but was damaged and forced to abort its patrol. It limped back to France, reporting that Allied destroyer escorts had become dramatically faster. German naval intelligence dismissed this as combat stress exaggeration. Over the next three months, the Buckley encountered submarines seven times.

In standard destroyer escort operations, the historical success rate was approximately 20%. The Buckley score was different. Seven contacts, five kills confirmed, one probable, one escape. The difference was speed. By October 1942, the Navy Department noticed that the USS Buckley was the most successful submarine hunter in the Atlantic Fleet.

Admiral King personally requested a technical analysis. The investigation revealed that the Buckley’s propeller assemblies were not built to standard specifications. The ship incorporated unauthorized modifications designed by an enlisted machinist mate. The Navy’s initial reaction was predictably bureaucratic.

Charges were prepared against Genevvesi and Henderson. The Buckley was ordered to return to Brooklyn for restoration of standard propeller assemblies. Courts marshall were scheduled. Admiral King intervened. The chief of naval operations had spent six months watching destroyer escorts fail to catch submarines. Now someone had built a faster ship and the Navy was preparing to court marshall him.

King’s order was direct. Cancel the courts marshall. Keep the modifications. Conduct a full engineering analysis. If the analysis confirmed the design was superior, implement it across the fleet. The engineering analysis took six weeks. Naval architects examined the Buckley’s propeller assemblies in detail. Their conclusion was unambiguous.

Chief machinist made Frank Genevvesy’s unauthorized design reduced propeller turbulence by 73%. This translated to 11% improvement in propeller efficiency. Ships using the modified design would be 2 to three knots faster and use 8 to 10% less fuel. The engineering team’s report included a remarkable acknowledgement.

The standard bureau of ships design used on every American warship for two decades was unnecessarily inefficient. Genevves working from practical observation rather than theoretical analysis had developed a solution that formally trained naval architects had dismissed as impossible. Admiral King ordered immediate implementation across all destroyer escorts under construction.

Over 200 ships would be modified. This would be called the Genevese modification in internal Navy documents. The impact was immediate. Destroyer escorts with the modification had operational speeds of 25 to 26 knots rather than 23. Submarines that could escape from standard escorts could not escape from modified escorts.

Submarine loss rates in the Atlantic increased sharply starting in early 1943. The German Navy noticed but couldn’t explain the change. Yubot crews reported that American destroyer escorts had become faster. German naval intelligence investigated whether engines had been upgraded. They never discovered the truth.

The improvement came from repositioning structural supports, a modification so simple that German engineers dismissed it as irrelevant. By mid 1943, the Battle of the Atlantic had turned decisively. Submarine sinkings exceeded submarine production. German crews couldn’t be trained fast enough. Many factors contributed to this reversal, but one factor historians often overlook was the increased speed of American destroyer escorts.

Statistical analysis shows that destroyer escorts with Genevese modifications achieved submarine kill rates approximately 40% higher than unmodified escorts. The broader implications went beyond submarine warfare. The Genevese modification demonstrated that naval architecture had fundamental blind spots.

Improvements were possible if the Navy was willing to listen to enlisted personnel. This realization triggered a cultural shift. The Bureau of Ships began actively soliciting suggestions from enlisted personnel. A formal program was established where machinist mates and technicians could submit design proposals. The results were remarkable.

Enlisted suggestions led to improvements in steam turbine efficiency, boiler designs, electrical systems, and dozens of other practical improvements that formally educated engineers had overlooked. Frank Genevvesi was promoted to warrant officer in January 1943. He was assigned to the Bureau of Ships as a technical consultant advising on practical engineering problems that conventional analysis couldn’t solve.

Before we reveal the final impact and legacy, I want to remind you to subscribe if you haven’t already, hit that subscribe button and turn on notifications so you never miss these incredible true stories. These are the stories that shaped history but were classified for decades. Now, let’s conclude with how one mechanic’s outlawed idea transformed naval warfare forever.

The post-war analysis revealed implications beyond destroyer escorts. The basic principle applied to every type of ship. The Navy began a systematic review of propeller installations across the entire fleet. Destroyers, cruisers, battleships, carriers, submarines, all had similar inefficiencies. A massive retrofit program began in 1946.

By 1950, virtually every ship in the United States Navy had been modified. The cumulative improvement was 7 to 9% better speed and 12 to 15% better fuel economy. The fuel savings alone justified the program economically. The Navy calculated that improved propeller efficiency saved approximately 200 million gallons annually.

At 1945 prices, this represented $60 million per year in direct savings. But the speed improvements had strategic implications. American carriers, cruisers, and destroyers of the Cold War era were consistently faster than Soviet equivalents, partly because American ships incorporated GOV’s principles, while Soviet naval architecture remained conventional.

The story influenced naval culture beyond technical matters. The Navy established the Naval Innovation Program in 1948, explicitly encouraging personnel at all levels to submit ideas. The program received over 50,000 suggestions in its first decade, implemented approximately 8,000, and generated measurable improvements.

Many valuable suggestions came from enlisted personnel with practical experience rather than officers with formal education. Private ship building companies adopted similar approaches. Major naval contractors began consulting with experienced naval personnel during design phases. This practice caught design flaws that conventional engineering missed.

The broader American defense industry learned from this experience. Aircraft manufacturers began consulting with crew chiefs. The principle that operators had valuable insights became standard practice. This cultural change contributed to American military technological superiority during the Cold War.

Soviet military development remained rigidly hierarchical. Design decisions were made by credentialed engineers and party officials. Input from ordinary soldiers and sailors wasn’t valued. The result was that Soviet equipment frequently had practical problems that American equipment avoided. Frank Genovves retired from the Navy in 1956 as a lieutenant commander.

An extraordinary achievement for someone who entered as an enlisted man without college education. His official record credited him with 12 design improvements beyond the original propeller modification. His unofficial influence was far greater. He had demonstrated that practical knowledge deserved equal respect with theoretical education.

Genevves died in 1973 at age 74. The full story remained partially classified until 1991 when declassification of World War II technical documents revealed the details. The USS Buckley served throughout World War II with distinction. She was credited with sinking five submarines, damaging three others, and escorting 73 convoys without losing a single merchant ship.

This record was exceptional among destroyer escorts. The Buckley was decommissioned in 1946 and scrapped in 1947. Before scrapping, her propeller assemblies were sent to Navy testing facilities for detailed analysis. Engineers studied them for years. The studies confirmed what Genevvesi had understood intuitively.

Positioning structural supports to minimize turbulence was more important than any other single factor in propeller efficiency. Modern naval architecture incorporates Genevese principles as fundamental design requirements. Naval architects learning their trade study the Genevese modification as a classic example of how practical observation can lead to theoretical breakthroughs.

Textbooks on marine engineering reference his work. The story is ultimately about the nature of innovation and the sources of expertise. Frank Genevvesi had no formal engineering education, no advanced degree, no credentials that would normally qualify someone to challenge naval architecture. What he had was 25 years of experience listening to propellers and observing how ships actually performed rather than how equations said they should perform.

His willingness to trust his experience over official specifications to make unauthorized modifications despite the risk of court marshal exemplified a peculiarly American approach to technical problems. The respect for practical knowledge over formal credentials, the willingness to challenge authority when authority was wrong, and the tolerance for rulebreaking when rules prevented improvement were cultural attributes that contributed to American technological leadership.

The German Navy had highly educated engineers, sophisticated theoretical analysis, and rigid adherence to proven designs. But German naval culture didn’t encourage enlisted personnel to suggest modifications. German bureaucracy didn’t tolerate unauthorized changes. German engineering excellence was constrained by cultural rigidity that prevented practical innovation.

The result was that American ships consistently outperformed German equivalence in practical operational measures. This practical superiority came from a cultural willingness to value hands-on experience alongside theoretical knowledge. The lesson extends beyond naval engineering to innovation generally.

Organizations that privilege credentials over competence that restrict decision authority to formally educated experts that punish unauthorized improvements consistently underperform organizations that empower people closest to problems to solve them. Frank Genevese’s unauthorized modification succeeded not despite his lack of formal education, but partly because of it.

He wasn’t constrained by theoretical assumptions about what was impossible. He simply observed that propellers operated inefficiently, calculated how to improve them, and implemented his solution when official channels rejected it. This pattern appears repeatedly in technological history. Important innovations often come from outsiders who don’t know what conventional wisdom says is impossible.

Organizations that recognize this, that actively seek input from practitioners, that tolerate unauthorized experimentation, consistently outperform organizations that rely exclusively on formal expertise. The United States Navy learned this lesson from Frank Genevvesi. A mechanic’s outlawed idea created not just one fast ship but transformed the entire fleet’s approach to engineering.

The cultural change contributed to American naval superiority for generations. Today, the principles Genev discovered through unauthorized experimentation are taught in every marine engineering program. Ships around the world incorporate design principles derived from his work. The outlawed idea has become orthodox engineering practice.

But the deeper lesson is about organizational culture and the sources of innovation. The mechanic who violated orders, the supervisor who concealed the violation, and the admiral who rewarded rather than punished them, all contributed to American victory and technological leadership. They demonstrated that sometimes progress requires breaking rules, that authority should be challenged when authority is wrong, and that results matter more than credentials.

Frank Genevese’s story reminds us that expertise comes in many forms, that practical knowledge deserves respect equal to theoretical education, and that organizations that empower practitioners achieve innovations that rigid hierarchies prevent. His unauthorized modification saved convoys, sank submarines, and helped win the Battle of the Atlantic.

More importantly, it demonstrated that American naval superiority came not just from industrial capacity or technological sophistication, but from a culture that valued ideas regardless of their source. The fastest warship was built by a mechanic who didn’t have permission, who violated direct orders, who risked court marshal, and who trusted his hands and his experience more than official specifications.

His outlawed idea became the foundation for generations of naval design, proving that sometimes the most important innovations come from the most unexpected places, and that the courage to break bad rules is as important as the wisdom to follow good ones.