The Metal Sample That Matched No Allied or Axis Alloy Records

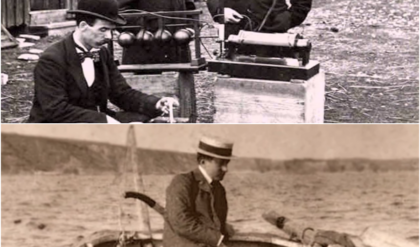

July 18th, 1945, Oakidge National Laboratory, Tennessee. Dr. Philip Morrison, 30-year-old metallurgist, was conducting what should have been routine work, analyzing metal fragments recovered from the Pacific theater to assess Japanese manufacturing capabilities. The war had ended in Europe 3 months earlier.

Japan’s surrender was clearly imminent, but intelligence work continued, cataloging enemy technology for postwar assessment. Sample Jac O731J arrived in a sealed envelope marked aircraft structural component Okinawa recovery June 12th 1945. The accompanying documentation stated it came from a downed Nakajima Key 84 fighter specifically from the wing spar structure.

The recovery team had labeled it simply as aluminum alloy unknown specification. Morrison’s job was identifying exactly which aluminum alloy the Japanese were using. Different alloys had different performance characteristics, strength, weight, fatigue resistance, corrosion properties. Understanding Japanese metallergy revealed their manufacturing capabilities and resource access.

It was intelligence work disguised as material science. The sample weighed 47 g, about the size of a domino, with machining marks indicating it had been cut from a larger structural component. Morrison began with visual inspection.

The metal appeared typical of aircraft aluminum, silver gray color, slightly rough surface texture from combat damage. No obvious unusual characteristics. Standard procedure required spectrographic analysis, heating the sample to vaporization temperature and measuring the wavelengths of light emitted by different elements. Each element produced a unique spectral signature like a fingerprint.

By identifying which spectral lines appeared, Morrison could determine the alloys exact composition. Each story hides truths that will shock you. Subscribe now to discover what comes next. Morrison placed a tiny fragment less than 1 g into the spectrograph’s electrode holder and initiated the test. The sample vaporized in the 6,000° arc, its atoms emitting light that the instrument’s prism separated into component wavelengths. The photographic plate recorded the resulting spectral lines. Developing the plate took 40

minutes. When Morrison examined the results under magnification, he immediately knew something was wrong. The major spectral lines matched aluminum as expected. The sample was primarily aluminum based. Additional lines matched zinc and magnesium, common alloying elements in aircraft aluminum. But there were other lines, faint but unmistakable spectral emissions at wavelengths that didn’t match anything in his reference charts. Morrison checked his spectral line database, a thick binder containing wavelength data

for all 92 known elements. The mysterious lines didn’t correspond to any element in the database. He considered possible explanations. Contamination from the recovery process, interference from atmospheric gases, equipment malfunction.

He ran the test again using a different fragment from the same sample and fresh equipment carefully cleaned to eliminate contamination. 40 minutes later, he examined the new spectral plate. The mysterious lines appeared in exactly the same positions. Whatever element was producing those spectral signatures was definitely present in the Japanese alloy.

Morrison spent the rest of the day consulting every metallurgy reference in Oakidge’s library. The spectral lines didn’t match iron, copper, chromium, nickel, or any other common alloying element. They didn’t match rare elements like burillium or lithium that occasionally appeared in specialized alloys. The lines simply didn’t match anything he could find.

The next morning, Morrison performed quantitative analysis, carefully measuring the intensity of each spectral line to calculate elemental concentrations. The results were precise. 80 89.3% aluminum, 7.2% zinc, 2.1% magnesium, 1.4% and 4% unknown element with trace amounts of iron and silicon, but it was the alloys physical properties that truly baffled Morrison.

Standard tensile strength testing showed the sample could withstand 340 megapascals of stress before failing, compared to 280 MPa for the best American aircraft aluminum alloys. Fatigue testing revealed the material could endure three times as many stress cycles as comparable US alloys before developing cracks.

Corrosion resistance exceeded anything in Allied metallurgy records. The Japanese had somehow created an aluminum alloy using an unidentified element at just 1.4% concentration that improved strength by 20%, tripled fatigue resistance and enhanced corrosion resistance. All properties critical for aircraft structures. It was a super alloy that shouldn’t exist according to everything Morrison knew about material science.

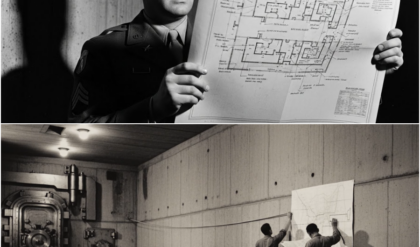

On July 25th, Morrison filed a report to the Manhattan Engineering District’s intelligence section. Sample O731J contains unidentified element producing spectral lines at wavelengths not corresponding to known metals. Request consultation with advanced chemistry specialists. Material properties suggest significant Japanese metallergical advancement requiring immediate investigation.

What Morrison didn’t know was that he had stumbled onto one of the war’s most remarkable stories of innovation born from desperation and discovered an element that would remain obscure for another 30 years before revolutionizing aerospace engineering. To understand how Japanese metallurgists created this mysterious alloy, we need to examine the resource crisis that forced them to innovate beyond anything their enemies achieved.

By 1943, Japan’s strategic situation was deteriorating rapidly. Allied submarines were systematically destroying Japanese merchant shipping, cutting the island nation off from critical raw material sources across its conquered territories. The statistics told a story of industrial strangulation, tin imports from Malaysia, reduced from 42,000 tons in 1942 to 3,000 tons in 1943.

Tin was essential for bronze bearings and solder in aircraft manufacturing. Nickel imports from Indonesia reduced from 7,000 tons in 1942 to 800 tons in 1943. Nickel was critical for high strength steel alloys used in aircraft engines and landing gear.

Chromium imports from the Philippines reduced from 12,000 tons in 1942 to one 500 tons in 1943. Chromium was necessary for corrosion resistant steel and high temperature alloys. Even aluminum production using domestic borite deposits suffered from shortages of alloying elements that made aluminum suitable for aircraft structures. Pure aluminum is too soft for structural applications.

It requires careful addition of zinc, magnesium, copper and other elements to achieve necessary strength. Standard allied aircraft aluminum designated 2024 in American terminology contained aluminum alloyed with 4.4% copper, 1.5% magnesium, and 0.6% manganese. Japan’s equivalent alloy designated super duralumin used similar composition. But by 1943, copper supplies were critically short. Japan needed alternative alloying approaches that didn’t depend on imported materials.

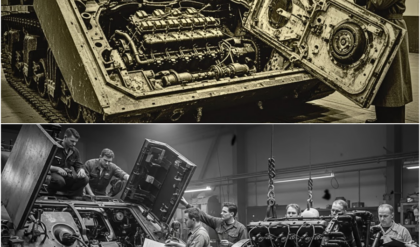

Japanese metallurgists at Sumitomo Metal Industries, Kobe Steel, and the Imperial Army’s Technical Research Institute received seemingly impossible directives. Developed stronger, lighter aluminum alloys using only domestically available elements.

No imported copper, nickel, or chromium, whatever they could extract from Japan’s own geological resources. Dr. Teo Wada, 43 years old, headed Sumitomo’s advanced alloy research section. In December 1942, he assembled a team of 12 metallurgists with a mandate to test every possible alloying approach that might substitute for materials Japan could no longer obtain. The team began systematically testing trace element additions to aluminum zinc magnesium base alloys.

They tried titanium from Japanese titanium sand deposits. Minimal improvement. They tried zirconium from imported minerals stockpiled before the war. some strength increase but unacceptable weight penalty. They tried every element they could obtain in sufficient quantity for testing.

In March 1943, a junior metallurgist named Kenji Nakamura suggested testing scandium. Most of the team had never heard of scandium. It was an obscure element discovered in 1879 by Swedish chemist Lars Frederick Nielson, but never found in concentrations worth commercial exploitation. The element appeared in some rare earth mineral deposits at roughly one part per million. So scarce that most chemistry textbooks gave it only brief mention.

But Nakamura had read a 1937 Soviet paper describing scandium’s crystal structure and theorizing it might inhibit grain boundary movement in aluminum alloys, a mechanism that could dramatically increase strength. More importantly, Japan had small deposits of scandium bearing minerals in volcanic soils of Kyushu Island. The concentrations were tiny, but they were domestic resources.

Wada authorized the experiment more from desperation than optimism. Extracting scandium from low concentration oes would be expensive and difficult. But if it worked, Japan would have an alloying element that nobody else was using, a potential advantage that didn’t depend on winning back control of Southeast Asian resource territories. The extraction process took 4 months.

By July 1943, Wad’s team had produced 340 gram of scandium metal, barely enough for preliminary alloy tests. They added scandium at various concentrations to aluminum, zinc, magnesium base alloys and evaluated mechanical properties. The results were extraordinary. At just 1.5% scandium addition, the aluminum alloys tensile strength increased by 22% compared to scandium free alloys.

Fatigue resistance, the ability to withstand repeated stress cycles without cracking, improved by 300%. The grain structure under microscope examination showed something remarkable. Scandium atoms were preventing aluminum crystal grains from growing during heat treatment, creating ultrafine grain structure that dramatically enhanced strength.

Would you have bet your nation’s industrial future on an element so rare that most scientists had never worked with it? Share your thoughts below and subscribe to this channel because we post powerful untold stories like this every single day. The metallergical mechanism wouldn’t be fully understood until 1960s research, but it worked like this.

Scandium’s atomic radius is slightly smaller than aluminums. When scandium atoms substitute for aluminum atoms in the crystal latice, they create localized strain fields that inhibit dislocation movement, the microscopic defects that allow metals to deform under stress. Fewer mobile dislocations mean higher strength.

Additionally, scandium forms stable compounds at grain boundaries that prevent grains from growing during heat treatment, maintaining fine grain structure that further enhances strength. Essentially, scandium was the perfect alloying element for aluminum if you could obtain enough of it, and Japan couldn’t. Between July 1943 and August 1945, Japanese industry produced only 23 kg of scandium metal.

For comparison, a single K84 fighter contained approximately 850 kg of aluminum alloy in its airframe. Even if Japan dedicated all available scandium to aircraft manufacturing, it could produce only enough scandium aluminum alloy for perhaps 200 aircraft components total. Wing spars, landing gear fittings, critical structural points where superior strengthtoe ratio justified the enormous cost. The decision was made to reserve scandium aluminum for elite fighter units.

The KI84 fighter equipped with the Imperial Army’s air defense units protecting Japan itself and the Kai 100 interceptor specifically designed to counter B29 bomber raids. These aircraft would receive scandium aluminum components in critical structural locations. Standard production aircraft would continue using conventional alloys.

This explained why sample O731J existed. The K84 shot down near Okinawa in June 1945 had been one of the select aircraft receiving advanced alloy components. Most K84s didn’t have scandium aluminum, only those deployed in homeland defense, where performance mattered most. But proving the sample contained scandium required Morrison to solve a mystery that would consume 3 months of research.

Morrison’s immediate problem in July 1945 was that he had spectral lines that didn’t match his reference database. The database was comprehensive. It contained spectral signatures for all elements commonly used in metallurgy. But scandium wasn’t commonly used.

In fact, scandium was so rarely encountered in practical metallurgy that Oakidge’s database simply didn’t include its spectral data. This wasn’t an oversight. Scandium was considered a laboratory curiosity with no industrial applications. Including its spectral lines in a working metalologist’s reference database would be like including spectral data for radioactive elements that existed only in microgram quantities in research labs. Technically complete but practically useless.

Morrison began searching through academic chemistry literature. He consulted the handbook of chemistry and physics. Scandium was listed with basic properties but no spectral line data. He checked metallergy journals from the 1930s and early 1940s. Nothing. Most publications that mentioned scandium at all discussed it only in context of rare earth mineral surveys or theoretical crystal chemistry.

Finally, in late September 1945, Morrison found a 1937 German publication site shift for anisher algami journal of inorganic and general chemistry. An article by researcher Herman Schnel titled spectroscop spectroscopic investigation of rare earths included comprehensive spectral line data for scandium and other rare earth elements. Morrison compared Schnell’s data to his spectral plates from sample or 731J, perfect match.

The mysterious lines corresponded exactly to Scandium’s emission spectrum. The unknown element was identified, but this created new questions more troubling than the original mystery. Scandium was extraordinarily rare, roughly one part per million in Earth’s crust, making it scarcer than lead, uranium, or most elements considered rare. Extracting it from mineral ores required sophisticated chemistry.

Using it as an alloying element was considered economically absurd when more common elements like copper or nickel achieved similar results. Yet Japan, a nation facing catastrophic resource shortages in 1943 Tata 45, had somehow produced scandium in sufficient quantity to alloy it into aircraft structures.

That implied either Japan had scandium deposits far richer than anywhere else on Earth, or Japanese metallergists had developed extraction processes so advanced they could economically process extremely low concentration or Morrison’s October 1945 report to army intelligence posed the question directly. Japanese use of scandium aluminum alloy implies metallurgical capabilities exceeding Allied knowledge.

recommend immediate investigation of Japanese research facilities to determine extent of advanced materials development. The investigation would reveal that Japan’s achievement was less about superior technology and more about desperate innovation, the willingness to pursue approaches that economically rational nations would reject as too expensive or impractical. But the discovery’s implications went far beyond explaining one metal sample.

If Japan had developed scandium aluminum alloys in 1943-45, their late war aircraft should have been significantly superior to what American intelligence had estimated. The investigation of Japanese metallurgical facilities began in September 1945. Immediately after occupation forces secured major industrial sites, teams from the US Army’s technical intelligence branch interviewed Japanese engineers, examined laboratory records, and assessed production facilities. Dr.

Bada’s team at Sumitomo had destroyed most documentation in the war’s final weeks following orders to prevent technology from falling into Allied hands, but enough records survived to reconstruct the program’s basic outline. Between mid 1943 and August 1945, Japan had conducted the world’s most extensive research program on scandium aluminum alloys, not because Japanese scientists were more advanced than Western counterparts, but because desperation had forced them to investigate materials everyone else dismissed as impractical. The production numbers told the story. 23 kg of scandium metal produced over 2

years, enough for approximately 1 1600 kg of aluminum scandium alloy at 1.4% scandium concentration. That alloy had been incorporated into roughly 200 aircraft, primarily KI 84 fighters and KI 100 interceptors deployed in homeland defense. American intelligence analysts began re-examining Pacific air combat records with new perspective.

If elite Japanese fighters had been equipped with airframe components 20 40% stronger and lighter than American intelligence estimated their combat performance should have shown anomalies better than predicted based on known Japanese manufacturing capabilities. The anomalies were there subtle but consistent. K84 fighters showed higher thanex expected climb rates in combat reports from late 1944 onward.

Pilots reported these aircraft could sustain tighter turns and more aggressive maneuvers than earlier Japanese fighters. Structural integrity was remarkable. Kai 84s often survived combat damage that should have been catastrophic based on expected aluminum alloy strength. Lieutenant Colonel James Sweeney, who had flown P-51 Mustangs against Kai 84s over Japan in early 1945, described the experience in postwar debriefings.

The Kai 84 was a handful, better than intelligence briefings suggested. They could outturn us at medium speeds, climb impressively, and take punishment that should have torn their wings off. We attributed it to good design, but maybe it was good materials, too.

The Kai 100 interceptor, introduced in March 1945, specifically to counter B29 raids, showed even more impressive performance. B-29 crews reported these aircraft climbing to 30,000 ft faster than any previous Japanese fighter and maintaining structural integrity during high-speed dives that typically caused earlier Japanese aircraft to shed wings or tail surfaces. American pilots assumed Japanese aerodynamic design had improved.

In reality, Japanese airframe design was conventional. The performance advantages came from materials that allowed lighter weight without sacrificing strength. An aircraft that weighs 200 kg less than its predecessor climbs faster and accelerates more quickly using the same engine. Scandium aluminum provided that weight savings in critical structures. But Japan’s industrial collapse meant the technology never reached mass production.

Only elite units protecting the home islands received scandium alloy aircraft. The vast majority of Japanese fighters, thousands of aircraft deployed across the Pacific, still used conventional aluminum alloys because scandium simply wasn’t available in industrial quantities.

The war ended before scandium aluminum could be deployed widely enough to affect strategic outcomes. But it raised uncomfortable questions for postwar American aerospace engineers. Had Japan facing defeat and resource starvation somehow innovated beyond the nation with the world’s largest industrial base. American aerospace industry learning of the Japanese discovery initiated scandium research programs in 1946.

But scandium remained too expensive and rare for practical use until the Soviet Union’s discovery of major deposits in the 1970s. The discovery of sample O731J’s scandium content became a classified footnote in postwar technical intelligence reports. The material sat in storage at Wright Patterson Air Force Base for decades, occasionally referenced in materials science literature, but never commercialized because scandium sources were too scarce to support industrial applications. That changed dramatically in the 1970s when

Soviet geologists discovered substantial scandium deposits in Ukraine and Kazakhstan. Soviet metallergists aware of the Japanese wartime research through captured German translations developed commercial production methods that finally made scandium aluminum economically viable for aerospace applications.

The MIG 29 fighter introduced in 1982 incorporated scandium aluminum alloys in critical airframe structures achieving weight savings of 15 to 20% compared to conventional aluminum alloys. The MIG 31 interceptor used scandium aluminum extensively in wing spars and fuselage frames.

Soviet aerospace industry had turned Japanese desperation innovation into Russian strategic advantage. American aerospace companies, alerted by Soviet advances, accelerated their own scandium aluminum development. But scandium remained expensive, $3,000 to $4,000 per kg compared to $2 per kg for conventional aluminum alloys. Economic viability required applications where weight savings justified enormous material costs.

Those applications existed in commercial aviation. Every kilogram of weight saved in an airliner translates directly to fuel efficiency or payload capacity. An aircraft flying 20 years might save millions of dollars in fuel costs if its airframe weighs a few hundred kg less. In the 1990s, Airbus began incorporating scandium aluminum alloys in A380 wing structures.

The alloys superior fatigue resistance made it ideal for wing components that experienced millions of stress cycles over an aircraft’s lifetime. Boeing followed with 787 Dreamliner fuselage components using scandium aluminum in high stress areas. Modern spacecraft development brought new applications.

SpaceX uses scandium aluminum alloys in Falcon rocket structures where every gram of weight saved allows additional payload capacity. The alloys combination of strength, lightweight, and excellent weldability makes it ideal for rocket tanks and structural frames. Today, the global aerospace grade scandium market is worth approximately 140 million annually. Annual production has reached 15 to 20 tons, nearly 1,000 times the total amount Japan produced during World War II.

China has become the dominant producer, controlling 70% of world scandium output from rare earth mining operations. The applications extend beyond aerospace. High performance bicycles use scandium aluminum alloy frames, lighter and stronger than standard aluminum. Baseball bats, lacrosse sticks, and other sports equipment benefit from the alloys combination of strength and lightweight.

Even consumer electronics occasionally use scandium aluminum where thin strong cases are required, but the aerospace applications remain most significant. Modern aircraft design pushes continuously toward lighter structures to improve fuel efficiency and reduce emissions. Scandium aluminum provides one of the few remaining opportunities for significant weight reduction without compromising strength or safety.

The Airbus A380s wing structure, for example, saves approximately 300 kg compared to conventional aluminum construction through strategic use of scandium aluminum alloys. Over the aircraft’s 25- year operational life, flying 3,000 hours annually, that weight saving translates to roughly $3.5 million in fuel cost reduction. The Scandium aluminum alloy costs perhaps $1.2 $2 million more than conventional aluminum, providing net savings of $2.

3 million, a compelling economic case for advanced materials. Sample O731J, the 47 g fragment that matched no records in 1945, is now displayed at the Smithsonian’s National Air and Space Museum in Washington, DC. The display includes Morrison’s original spectral analysis plates showing the mysterious lines that led to Scandium’s identification.

A placard explains the sample’s significance. This aluminum alloy fragment recovered from a Japanese Kai 84 fighter in 1945 contains scandium, an element so rare that Japanese metallergologists use of it seemed economically absurd. Yet this alloyy’s strength exceeded Allied materials by 40%, demonstrating that desperate innovation sometimes achieves what abundant resources cannot.

Japanese scientists facing catastrophic shortages discovered an alloy combination that would define 21st century aerospace engineering. The sample represents both Japan’s remarkable materials, science achievement, and a lesson about innovation born from necessity rather than plenty. Dr. Philip Morrison, who first identified the sample’s unusual properties, had a distinguished career in physics after World War II.

He taught at MIT from 1946 until retirement in 1997, contributing to nuclear physics, astrophysics, and science education. In a 1989 interview, he reflected on sample 0731J. That piece of metal taught me humility about technological assumptions. We assumed American industrial might guarantee material superiority. We were wrong.

The Japanese with a fraction of our resources achieved something we hadn’t even attempted. Not because they were smarter, because they were desperate. Desperation eliminates the luxury of dismissing ideas as too expensive or impractical. Sometimes constraints force innovation that abundance would never attempt. Dr.

Teo Wada who led Sumitomo’s Scandium aluminum research survived the war and continued in material science until his death in 1978. He never received significant recognition in Japan where postwar focus emphasized rebuilding rather than celebrating wartime achievements. But Soviet and later American metallergists who built on his work acknowledged his pioneering research in developing the first practical scandium aluminum alloys.

The broader lesson from sample O731J extends beyond materials science into questions about innovation, resources, and how constraint sometimes breeds creativity that abundance never produces. American aerospace industry in 1943-45 had essentially unlimited access to every material needed for aircraft manufacturing.

copper, nickel, chromium, manganese, all available in quantities sufficient to meet demand. There was no pressure to explore exotic alternatives because conventional alloys worked adequately and supplies were secure. Japan had none of those advantages. Facing critical shortages of basic alloying elements, Japanese metallurgists were forced to investigate approaches that Western engineers dismissed as economically irrational.

Using scandium, an element so rare it cost thousands of times more than conventional alloying elements, only made sense when conventional elements weren’t available at any price. This pattern appears repeatedly in technological history. The Apollo program’s development of miniaturized electronics arose partly from weight constraints in spacecraft.

Every gram mattered. Digital photography developed faster in Japan than America, partly because Japanese companies faced space constraints in consumer electronics that made miniaturization economically valuable. Electric vehicles advanced rapidly in Norway, partly because high gasoline prices and tax policies made alternatives economically competitive.

Constraint forces innovation. Abundance permits continuation of adequate solutions. The nation with unlimited resources often continues using good enough technology because the investment required to develop better alternatives isn’t justified when current approaches work acceptably.

Japan’s development of scandium aluminum alloys embodied this principle perfectly. Japanese metallergists achieved a breakthrough that would define future aerospace materials not because they were better funded or more scientifically advanced than American counterparts, but precisely because they lacked the resources to continue using conventional approaches.

What’s more remarkable to you? That Japan innovated beyond everyone else while losing the war? Or that it took American industry 50 years to fully utilize what desperate Japanese scientists discovered in 1943? Share your thoughts below. Subscribe to this channel for powerful untold stories every single day. And tomorrow, we’ll reveal another incredible story about technology that changed everything precisely because someone had no choice but to try the impossible. The metal sample that matched no allied or axis alloy records became more than a

metallurgical curiosity. It became evidence that desperate innovation sometimes achieves what abundant resources cannot. that the nation with everything available may be slower to discover alternatives than the nation with nothing left to lose.

Today, when scandium aluminum alloys reduce aircraft weight and improve fuel efficiency, when spacecraft frames use materials developed from Japanese wartime research, when every major aerospace manufacturer specifies alloys first created in resource starve Japan, we see sample O731J’s legacy. The 47 g fragment that confused Philip Morrison in 1945 pointed toward a future where material science would transcend the limitations everyone accepted as permanent.

Japanese metallergists in 1943 facing impossible shortages discovered something that would take the rest of the world decades to fully appreciate that sometimes the rarest element used in smallest quantities creates the most revolutionary change. And that innovation doesn’t always come from laboratories with unlimited budgets.

Sometimes it comes from desperate engineers with no alternatives and one last impossible idea worth